LDMCF-30/15AZ Plasma Lon Nitriding Furnace With Auxiliary Heating

Samy

LDMC-30/15AZ

| Availability: | |

|---|---|

| Quantity: | |

What is auxiliary heating?

ion nitriding furnaces, the heating of workpieces relies entirelyon the heat generated by the plasma bombarding the surface of the workpieces.This approach is "from the surface to the core".

The auxiliary heating system is a set of heating devices (usually resistanceheating rods or heating plates) independently installed in the vacuum furnace body.It can radiate heat the workpiece before, during or independently of the plasmastartup.

In simple terms, it is equivalent to installing an "electric furnace" inside theion nitriding furnace, achieving dual or independent heating of the workpiece.

Application:

As an effective steel and alloy surface strengthening technology, ion nitriding has been widely used in the industrial field. Ion nitriding is different from traditional gas nitriding. Ion nitriding is mainly used for surface normalizing, quenching and tempering and ion nitriding treatment of alloy structural steel, bearing steel, spring steel, die steel, tool steel and other materials.

LDMCF-30/15AZ series Plasma ion nitriding equipment

Main technical indicators:

| Model | LDMCF-30/15AZ |

Output voltage | 0-1000V continuously adjustable |

Maximum output average current | 30A |

Pulse peak current | 60A |

Pulse frequency | 1000Hz |

Furnace working volume | φ600×800mm |

| Treated maximum surface area | 3 m² |

Working temperature | 900℃ |

Rated load | 300KG |

Ultimate vacuum degree | ≤6.67Pa |

Pressure rise rate | ≤0.13Pa/min |

Vacuum to 20Pa time | ≤30min |

Arc extinguishing time | ≤15μs |

Temperature control accuracy | ±1°C |

Pressure control accuracy | ±1Pa |

Process | automatic control |

Equipment lifting | effective stroke 1000mm |

Plasma Ion Nitriding equipment features:

1.Coordinated Temperature Control with Dual Heat Sources

The equipment is equipped with plasma glow discharge heating and an independent auxiliary heating module. It can not only realize nitriding reaction on the workpiece surface by means of plasma, but also quickly raise the overall temperature in the furnace and reduce the temperature difference in the furnace cavity through auxiliary heating. It achieves precise temperature control in a wide range of 50℃-900℃ with a temperature control accuracy of ±3℃, meeting the differentiated heat treatment process requirements of workpieces of different materials.

2.High-Efficiency Nitriding Modification Effect

The furnace adopts a closed vacuum chamber design, combined with an accurate nitrogen/hydrogen mixed atmosphere control system, which can form a uniform and dense nitriding layer on the workpiece surface. The thickness of the nitriding layer can be controlled between 0.01mm-0.5mm, which significantly improves the wear resistance, corrosion resistance and fatigue resistance of the workpiece and extends the service life of the workpiece by 3-5 times.

3.Intelligent and Precise Control

It is equipped with a fully automatic PLC control system and a touch operation screen, which can preset process parameters such as nitriding temperature, holding time, and atmosphere ratio, and support real-time display of process curves and data storage and traceability. At the same time, it is equipped with multiple safety protection devices such as over-temperature alarm and vacuum degree abnormality warning to ensure stable operation and operation safety of the equipment.

4.Adaptation to Diverse Working Conditions

The furnace cavity specifications can be customized (from φ300×400mm small cavity to φ1200×1500mm large cavity), which can not only meet the small-batch sample research and development in the laboratory, but also adapt to large-scale production in factories. The equipment is also equipped with a rapid cooling module, which can shorten the workpiece cooling cycle and improve the overall production efficiency.

5.Energy-Saving and Environmentally Friendly Design

The furnace body adopts a multi-layer thermal insulation structure with heat loss as low as below 8%. The auxiliary heating module can be intelligently started and stopped according to process requirements, saving 15%-20% energy compared with traditional plasma nitriding furnaces. It has no open flame and no exhaust gas emission, complying with industrial green production standards.

LDMCF-30/15AZ series plasma ion nitriding equipment configuration table

Name | Specification introduce | Qty |

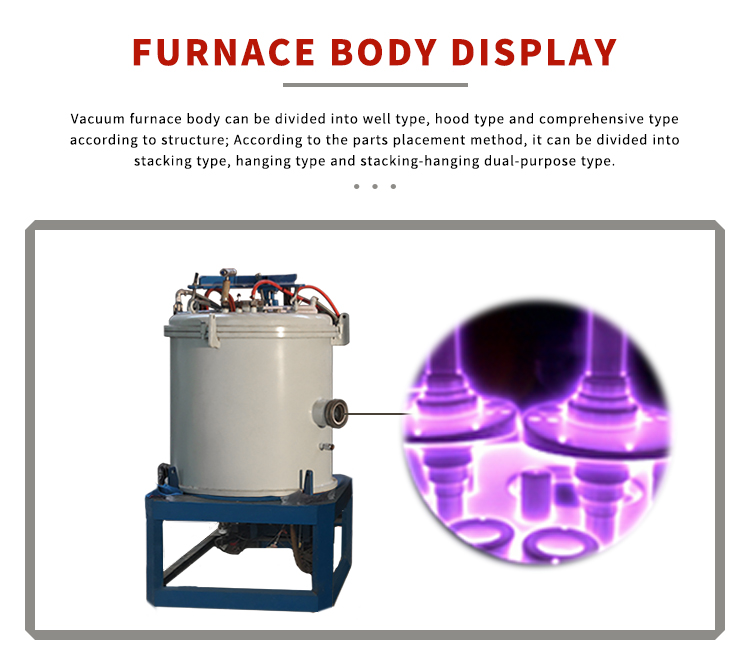

Vacuum furnace body | Chamber size:φ600×800mmH | 1 |

Vacuum pump | 2X-15 | 1 |

Electric vacuum butterfly valve | China GI-50 | 1 |

Vacuum solenoid valve | China DDC-JQ50 | 1 |

Mass flow controller | China D07 | 2 |

Film type absolute pressure vacuum gauge | China ZJ-1C | 1 |

Pressure control | Japan SR3 | 1 |

Temperature control | Japan SRS13 | 1 |

Rectifier transformer | China (36KVA oil-immersed) | 1 |

PLC(Programmable controller) | Mitsubishi FX series from Japan | 1 |

Industrial PC | 15" color touch-able display | 1 |

Equipment lifting device | Effective stroke 1000MM(hydraulic lifting) | 1 |

Cooling tower (tank) | Flow ≥2M3/h | 1 |

LDMCF-3015AZ Series Plasma Ion Nitriding Furnace Selection and Function

Model | LDMCF-30/15A | LDMCF-30/15AZ |

Chamber size | ¢600x800mm | ¢600x800mm |

Heating power(kw) | 30 | 30 |

Limited vacuum(Pa) | ≤6.7 | ≤6.7 |

Rising rate(Pa/min) | ≤0.13Pa | ≤0.13Pa |

Max loading(kg) | 300 | 300 |

Treated maximum surface area | 3.0㎡ | 3.0㎡ |

Normal operating temperature(℃) | 850±50 | |

Maximum operating temperature(℃) | ≤900 | ≤900 |

Maximum peak current(A) | 60 | 60 |

Maximum current(S) | 30 | 30 |

Maximum output voltage(V) | 0-1000V Continuously adjustable | |

Frequency(Hz) | 1000 | 1000 |

Control mode | Fixed frequency width adjustment | |

Output waveform | Rectangular square wave | |

Arc Speed | ≤15μs | |

Temperature control mode | PID Automatic control | |

Pressure control mode | PID Automatic control | |

Pressure sensor type | Absolute pressure transmitte | |

Flow control mode | PID Automatic control | |

Ammonia flow-meter type | Mass flow-meter | |

Carbon flow-meter type | Mass flow-meter | |

Parameter input mode | Touch screen input | |

Parameter recording mode | Computer automatic input | |

Manual operation mode | Yes | |

Automatic operation mode | Yes | |

Programmable controller(PLC) | Yes | |

Industrial control computer | Yes | |

Furnace body lifting system | No | YES |

Furnace cooling mode | Multi-channel water inlet manual adjustment | |

Control cabinet size | 1400*700*2000mm | |

Product Detail Image:

Oversea Installation and Training Service: